Protect Your Investment From Preventable Damage

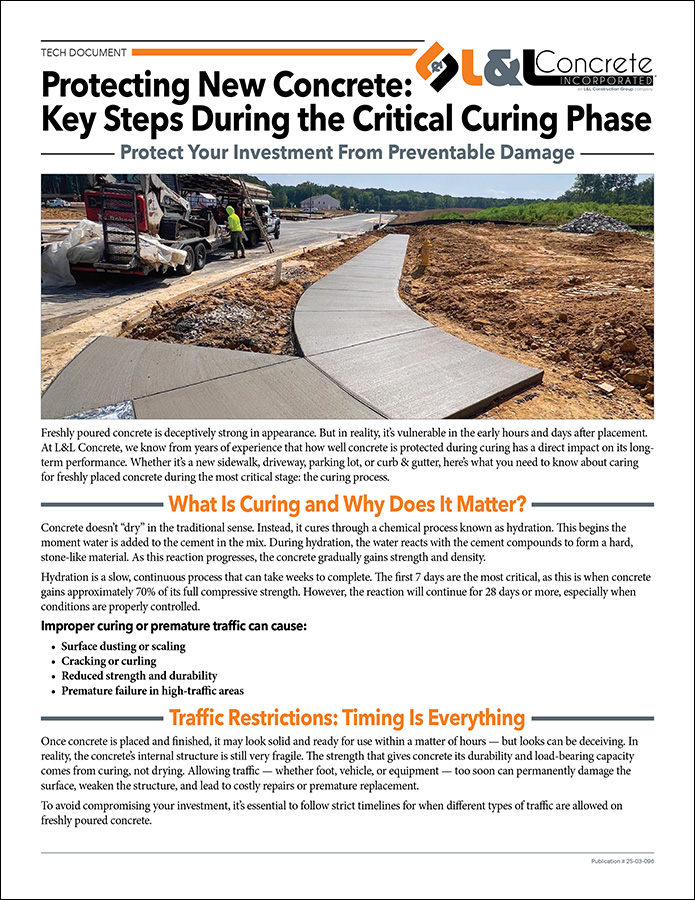

Freshly poured concrete is deceptively strong in appearance. But in reality, it’s vulnerable in the early hours and days after placement. At L&L Concrete, we know from years of experience that how well concrete is protected during curing has a direct impact on its long-term performance. Whether it’s a new sidewalk, driveway, parking lot, or curb & gutter, here’s what you need to know about caring for freshly placed concrete during the most critical stage: the curing process.

What Is Curing and Why Does It Matter?

Concrete doesn’t “dry” in the traditional sense. Instead, it cures through a chemical process known as hydration. This begins the moment water is added to the cement in the mix.

During hydration, the water reacts with the cement compounds to form a hard, stone-like material. As this reaction progresses, the concrete gradually gains strength and density.

Hydration is a slow, continuous process that can take weeks to complete. The first 7 days are the most critical, as this is when concrete gains approximately 70% of its full compressive strength. However, the reaction will continue for 28 days or more, especially when conditions are properly controlled.

Improper curing or premature traffic can cause:

- Surface dusting or scaling

- Cracking or curling

- Reduced strength and durability

- Premature failure in high-traffic areas

Traffic Restrictions: Timing Is Everything

Once concrete is placed and finished, it may look solid and ready for use within a matter of hours — but looks can be deceiving. In reality, the concrete’s internal structure is still very fragile. The strength that gives concrete its durability and load-bearing capacity comes from curing, not drying. Allowing traffic — whether foot, vehicle, or equipment — too soon can permanently damage the surface, weaken the structure, and lead to costly repairs or premature replacement.

To avoid compromising your investment, it’s essential to follow strict timelines for when different types of traffic are allowed on freshly poured concrete.

Foot Traffic: Wait at least 24–48 hours

Pedestrians should avoid the surface for the first full day after placement, ideally two days. During this time, the concrete’s surface is soft and susceptible to scuffs, gouges, or premature micro-cracking.

Vehicle Traffic: Wait a minimum of 7 days

Even though the concrete may appear solid within 24–48 hours, it takes at least 7 days to gain sufficient compressive strength to support the weight of cars, trucks, or equipment. Allow longer curing time for heavy vehicles, trailers, or construction equipment. 10–14 days is recommended where applicable.

Heavy Loads and Pressure Points: Avoid them completely during early curing

Don’t park, store, or drag heavy objects over new concrete. Doing so may lead to internal cracking that won’t be immediately visible, but will reduce longevity and load-bearing ability over time.

Physical Protection During Curing

Curing isn’t just about time. It’s also about shielding the concrete from external damage and interference. While the chemical hardening process is underway, the surface is especially vulnerable to physical impacts, abrasions, and contamination. Without proper physical protection, the concrete’s finish can be marred, its strength reduced, or its surface integrity compromised.

We strongly recommend taking active measures to protect the pour site. Common protective measures include:

- Barriers, cones, or caution tape to keep foot and vehicle traffic off the pour

- Covers or canopies for protection against rain, strong sun, or temperature swings

- Warning signage for workers, residents, or passersby

These aren’t just for show — they’re critical in preventing costly damage and rework. These protective measures are critical during the first 48–72 hours, but depending on the conditions and application, they may need to remain in place longer. It’s a simple investment in preventing expensive setbacks.

Environmental Factors to Watch

Weather and site conditions have a major influence on how well concrete cures. Because the hydration process depends on both moisture and temperature, extremes in either direction can disrupt proper curing. Understanding and preparing for environmental factors is essential to achieving a strong, durable slab. Here’s how to mitigate common risks:

Hot or windy weather? Increases evaporation, disrupting the hydration process. To prevent this, use windbreaks, sunshades, or coverings to slow down evaporation and help maintain a stable curing environment.

Cold weather? Concrete can freeze before it sets. Insulated blankets may be needed to maintain proper temperatures.

Rain? Can ruin surface finish if it falls before the concrete sets. Protect the area with plastic sheeting or tarps if rain is expected.

The Bottom Line

Protecting freshly poured concrete during the curing phase is not just a best practice — it’s a critical step that directly affects the quality, appearance, and lifespan of the finished product. The curing window represents a short but essential period in which the concrete develops the strength and durability it will rely on for decades of use. Whether you’re a builder, property owner, or facilities manager, understanding and respecting this process is key to getting the full value from your concrete installation.

Too often, early surface damage, premature cracking, or disappointing performance can be traced back to one cause: improper care during curing. And while concrete is a tough and reliable material, it can’t compensate for neglect during its most vulnerable stage. A little attention up front can prevent major issues down the road—saving time, money, and frustration.