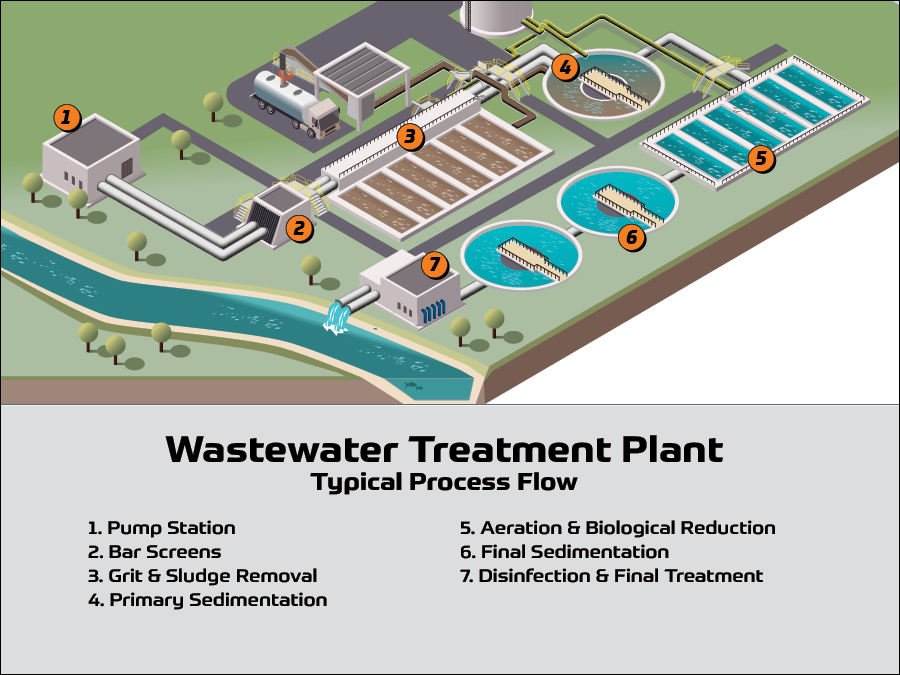

The primary goal of a wastewater treatment plant is to remove as much of the suspended solids as possible from the water before releasing it back into the environment. When solids break down in the water, they use up valuable oxygen that plants and animals living in the water rely on.

The staff of L&L Concrete’s Industrial / Commercial division has specialized experience in concrete construction of wastewater plants and pump stations. In addition to building the concrete forms, being a member of the L&L Construction Group family of companies allows us facilitate other key services, including excavation, site preparation and utilities.

Construction of a wastewater treatment plant involves many important components. Some of the key elements include:

Civil Construction

Construct the civil infrastructure, including excavation, foundations, and structural elements for treatment units, tanks, and buildings.

Wastewater treatment plants are typically situated in low-lying areas, often in proximity to a river where treated water can be discharged. In cases where the plant is constructed at an elevation higher than ground level, pumping is required to lift the wastewater to the facility.

Pump Station

A pump station at a wastewater treatment facility, also known as a lift station or pumping station, is a crucial component of the overall wastewater infrastructure. Its primary function is to lift or pump wastewater from a lower elevation to a higher elevation, allowing for the continuation of the wastewater flow through the treatment process. This becomes necessary when the treatment plant is located at an elevation higher than the areas it serves.

The pump station is equipped with pumps that are responsible for lifting the wastewater. These pumps overcome the force of gravity to move the wastewater from a lower level to an elevated position, ensuring a continuous flow through the treatment process.

The pump station typically contains a wet well, which is a storage chamber where wastewater collects before being pumped. The wet well helps regulate the flow of wastewater and prevents rapid pump cycling.

Primary Treatment

Install and construct primary treatment units, such as screens and grit chambers, which remove large debris and settleable solids from the wastewater. The Primary Treatment process removes approximately 60 percent of suspended solids from wastewater. Additionally, this treatment includes the aeration (stirring up) of wastewater to reintroduce oxygen.

Secondary Treatment

Install biological treatment processes, such as activated sludge systems or trickling filters, to further break down organic pollutants in the wastewater. Over 90 percent of suspended solids are eliminated through the Secondary Treatment process.

Tertiary Treatment (if needed)

Include additional treatment processes, such as filtration or chemical treatment, to achieve higher levels of water quality if required by local regulations.

Disinfection

Install disinfection systems, often using chlorine or ultraviolet (UV) light, to kill remaining pathogens in the treated water.

Sludge Handling

Construct facilities for handling and treating the sludge generated during the treatment process. This may include digesters, dewatering systems, and sludge disposal methods.

Utilities and Infrastructure

Establish supporting infrastructure such as power supply, water supply, and wastewater disposal systems for the treatment plant.

It’s important to note that the specific details of the construction process may vary depending on the type of wastewater treatment plant, its size, and the treatment technologies employed. Additionally, adherence to environmental regulations and community engagement are crucial aspects throughout the construction process.

Build your wastewater infrastructure with L&L Concrete, your premier partner in constructing robust and reliable wastewater facilities and pump stations. Our Industrial/Commercial Division staff bring unparalleled expertise to the table, seamlessly blending precision engineering with top-notch concrete craftsmanship. Our dedicated team specializes in creating durable structures that stand the test of time, ensuring the smooth flow of wastewater from collection to treatment. Whether it’s designing pump stations with cutting-edge technology or crafting resilient concrete structures for wastewater treatment plants, L&L Concrete is your trusted partner for sustainable solutions — building the foundation for a cleaner, more efficient tomorrow.

Follow us on Facebook and LinkedIn. L&L Concrete Incorporated is a proud member of L&L Construction Group, along with our sister companies, Triangle Ready Mix and East Coast Civil Group.